API Supply Chain: How Generic Drugs Move from Factory to Your Medicine Cabinet

When you pick up a generic pill, you’re holding a product shaped by a global API supply chain, the network that produces, transports, and delivers the active pharmaceutical ingredient—the core chemical that makes a drug work. Also known as active pharmaceutical ingredient, or API, this is the part of the medicine that actually treats your condition. Without a stable, reliable API supply chain, even the best-designed drug can’t reach the shelf. Most generic drugs rely on APIs made in just a few countries, especially India and China. These facilities follow the same quality rules as U.S. brands, but the distance, political shifts, and production delays can cause sudden shortages. A single factory shutdown in Hyderabad or Shanghai can ripple across continents, leaving pharmacies empty and patients scrambling.

It’s not just about where the API is made—it’s about how it moves. The pharmaceutical supply chain, the full system that turns raw chemicals into packaged pills, including testing, packaging, shipping, and regulatory approval involves dozens of steps, each a potential failure point. Contamination, paperwork errors, or customs delays can halt shipments. And while brand-name companies often own their own API production, generic makers depend on third-party suppliers. That means if one supplier cuts back or raises prices, dozens of generic drugs can spike in cost—or vanish entirely. This isn’t theory. In 2020, a shortage of metformin’s API caused delays for millions of diabetics. In 2022, a single API plant fire in India led to nationwide shortages of antibiotics like amoxicillin.

That’s why the generic drug manufacturing, the process of turning APIs into finished pills, including formulation, compression, coating, and quality checks process matters more than most people realize. It’s not just about copying a brand-name drug. It’s about matching purity, stability, and release timing—exactly. A small change in how an API is handled during manufacturing can lead to capping, inconsistent dosing, or even contamination, as seen in several FDA warnings over the past five years. These aren’t random mistakes. They’re often tied to pressure on manufacturers to cut costs in a hyper-competitive market. When you see a generic drug priced 90% lower than the brand, ask: what’s being sacrificed along the way?

The API supply chain isn’t just a logistics puzzle—it’s a public health issue. Your medicine’s safety, availability, and price all depend on it. Below, you’ll find real stories from patients and providers who’ve felt the impact: from pills that didn’t work because of poor manufacturing, to cross-border prescriptions that saved lives when local supplies failed. You’ll also learn how regulatory gaps, patent battles, and corporate decisions shape what ends up in your medicine cabinet. This isn’t abstract. It’s personal. And it’s happening right now.

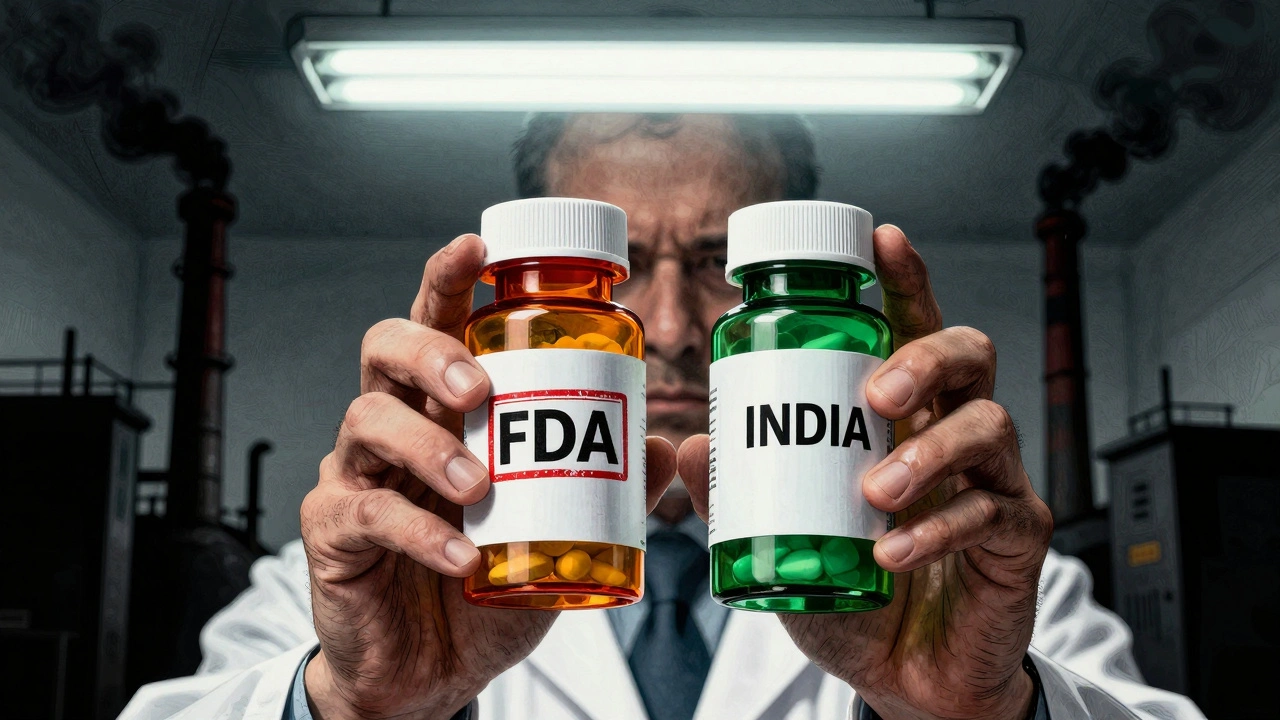

China and India Manufacturing: Risks and FDA Monitoring in Pharmaceuticals

China and India dominate global pharmaceutical manufacturing, but FDA monitoring reveals stark differences in quality control. India leads in compliance, while China supplies most APIs-but with higher risk. Here’s what you need to know.

Read More